- Home

- Products

- Glass Washing Machine

- Glass Washing Machine with High Efficiency and Energy Saving

Electronic Glass Washing Machine-EWD 1100THQ

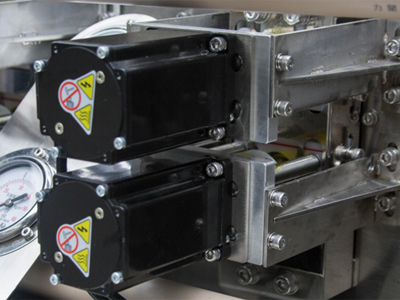

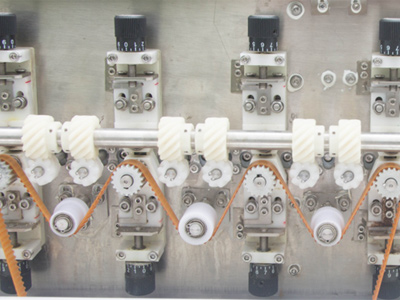

This flat glass washing machine is designed to pre-treat medium sized glass before coating, packing and laminating. The glass washing machine body is constructed from stainless steel for both aesthetic appearance and rust prevention to ensure that the glass remains uncontaminated. The electronic components feature smart PLC control which can be operated manually or automatically, guaranteeing convenient use and excellent performance with its basic construction. The conveyor and brush speed can be adjusted separately, to make sure a stable performance. Experience seamless automation with our cutting-edge machine that features automatic loading and unloading capabilities, eliminating the need for manual intervention.

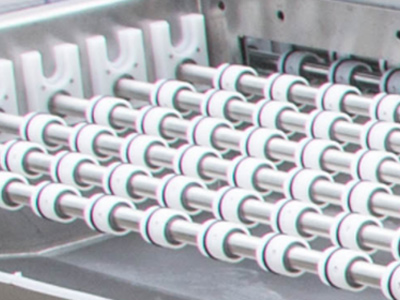

Technical Data- Distance between conveyor rollers: 60 mm

- Brush outer diameter: 70mm (arranged at the top and bottom)

- Machine material: SUS304 (& = 3.0 mm) main board, stainless steel frame

- Workpiece size: 7 inches and above

- Workpiece thickness: 0.4-2.0 mm

- Conveyor speed: 0.5-5.0 m/min (variable frequency stepless adjustable)

- Conveying shaft diameter: 17 mm, roller outer diameter: 32 mm

- Power supply: three-phase 380 V 50 HZ

- Maximum power: 72 kW

- Maximum operating temperature of equipment: 60℃

- Effective width: 1100 mm

- Total consumption of pure water: 30 L/min

Medium Size Flat Glass Washing Machine, EWD800KLQ

Elevate your glass processing with our horizontal flat glass washing machine, ideal for pre-washing medium-sized glass prior to cutting and after CNC processing or grinding. Boasting a sleek stainless steel body, it not only exudes elegance but also shields against glass contamination by preventing rust. The electrical parts are equipped with intelligent PLC control, allowing for seamless transitions between manual and automatic operations. With its straightforward design, reliable performance, and user-friendly interface, operating this equipment is easy.

Technical Data- Distance between drive rollers: 60 mm

- Brush outer diameter: 70mm (arranged at the top and bottom)

- Machine material: SUS304 (& = 3.0 mm) main board, stainless steel frame

- Workpiece size: 7 inches and above; maximum width: 700 mm

- Workpiece thickness: 0.4-3.0 mm

- Conveyor speed: 0.5-5.0 m/min (variable frequency stepless adjustable)

- Conveying shaft diameter: 17 mm, roller outer diameter: 32 mm

- Power supply: three-phase 380 V 50 HZ

- Maximum power: 36 kW

- Maximum operating temperature of equipment: 60 ℃

- Effective width: 800 mm

- Total consumption of pure water: 25 L/min

Electronic Flat Glass Washing Machine, EWD540SYH

Our cutting-edge flat glass washing machine is designed specifically for washing electronic glass following screen printing. With its sleek stainless steel structure, not only does it exude beauty and elegance, but it also eliminates the risk of glass contamination due to rust. The electrical component features advanced PLC intelligent control, allowing for effortless manual or automatic operation. Additionally, the conveyor and brush speed can be adjusted independently, ensuring the equipment operates smoothly and reliably. Experience the superior decontamination capabilities and high product yield that sets this equipment apart.

Technical Data- Distance between drive rollers: 35 mm

- Brush outer diameter: 41 mm (arranged at the top and bottom)

- Machine material: SUS304 (& = 3.0 mm) main board, stainless steel frame

- Workpiece size: 4 inches and above (Compatible to clean 2.5D and 3D glass, with arc height within 5mm)

- Workpiece thickness: 0.4-3.0 mm

- Conveyor speed: 0.5-5.0 m/min (variable frequency stepless adjustable)

- Conveying shaft diameter: 12 mm, roller outer diameter: 25 mm

- Power supply: three-phase 380 V 50 HZ

- Maximum power: 98 kW

- Maximum operating temperature of equipment: 60℃

- Effective width: 540 mm Total consumption of pure water: 20 L/min

Electronic Flat Glass Washing Machine, EWD540CNC

This cutting-edge flat glass washer is ideal for pre-washing electronic glass after CNC, grinding or polishing. Its PVC construction not only adds a touch of beauty and elegance but also provides protection against rust and glass contamination. The electrical components feature intelligent PLC control, allowing for both manual and automatic operation. Experience the reliability of its stable performance and enjoy the straightforward and user-friendly operation it offers.

Technical Data- Distance between drive rollers: 35 mm

- Brush outer diameter: 41 mm (arranged at the top and bottom)

- Machine material: NANYA transparent PVC board (& = 10 mm) main board, stainless steel frame

- Water tank material: Ivory PVC board (& = 10 mm)

- Workpiece size: 4 inches and above, maximum width: 400 mm

- Workpiece thickness: 0.4-3.0 mm

- Conveyor speed: 0.5-5.0 m/min (variable frequency stepless adjustable)

- Conveying shaft diameter: 12 mm, roller outer diameter: 25 mm

- Power supply: three-phase 380 V 50 HZ

- Maximum power: 28 kW

- Maximum operating temperature of equipment: 45℃

- Effective width: 540 mm

- Total consumption of pure water: 20 L/min

Electronic Flat Glass Washing Machine, EWD540MJH

Our electronic flat glass washer is designed specifically for efficiently pre-washing electronic glass post-grinding. Its sophisticated 304 stainless steel structure not only adds a touch of elegance but also prevents any potential glass contamination due to rust. The electrical components incorporate advanced PLC intelligent control, offering the flexibility of manual or automatic operation. With stable performance and user-friendly functionality, the glass washing machine ensures a straightforward and convenient operation experience.

Technical Data- Distance between drive rollers: 35 mm

- Brush outer diameter: 41 mm (arranged at the top and bottom)

- Machine material: 304 steel plate (& = 3.0mm) main board, stainless steel frame

- Water tank material: 304 steel plate (& = 1.5mm)

- Workpiece size: 4 inches and above, maximum width: 80 mm

- Workpiece thickness: 0.4-3.0 mm

- Conveyor speed: 0.5-5.0 m/min (variable frequency stepless adjustable)

- Conveying shaft diameter: 12 mm, roller outer diameter: 25 mm

- Power supply: three-phase 380 V 50 HZ

- Maximum power: 28 kW

- Maximum operating temperature of equipment: 60℃

- Effective width: 540 mm

- Total consumption of pure water: 20 L/min

Sapphire Flat Glass Washing Machine, EWD260LBS

Our sapphire flat glass washer is specifically designed to effortlessly wash small-sized sapphire glass both before and after screen printing, as well as after the coating process. Crafted with a stainless steel structure, it not only exudes an elegant appearance but also safeguards the glass from rust-induced contamination. Featuring PLC intelligent control in its electrical components, this glass cleaning machinery offers the flexibility of manual or automatic operation, ensuring stability and user-friendly functionality. With its remarkable decontamination capabilities and exceptional cleaning efficiency, this equipment stands out as a powerful solution.

Technical Data- Distance between drive rollers: 19 mm

- Brush outer diameter: 26 mm (arranged at the top and bottom)

- Machine material: SUS304 (& = 3.0mm) main board, stainless steel frame

- Workpiece size: 55 mm*60 mm

- Workpiece thickness: 0.3-1.5 mm

- Conveyor speed: 0.5-4.0 m/min (variable frequency stepless adjustable)

- Conveying shaft diameter: 8 mm, roller outer diameter: 13 mm

- Power supply: three-phase 380 V 50 HZ

- Maximum power: 50 kW

- Maximum operating temperature of equipment: 60℃

- Effective width: 260 mm

- Total consumption of pure water: 15 L/min

Get in Touch

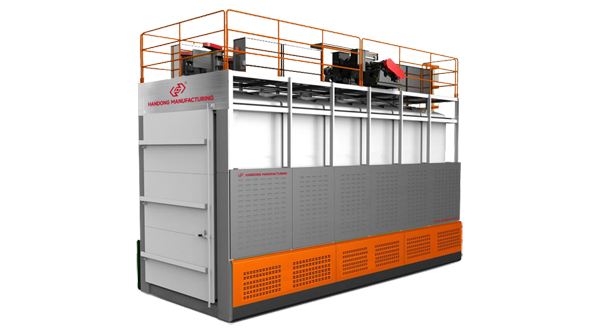

Handong is an industry-leading glass processing machinery manufacturer with rich experience in glass processing and laminated glass production industry. We are committed to producing the state-of-the-art laminated glass production line and glass processing plants to our customer, including glass washing machine, heat soak furnace, glass loading table, autoclave and more.

We conducted strict quality management system to control the quality of each glass machine, which is produced with the highest efficiency, accuracy, and stability to exceed your expectation. With strong manufacturing capability, experienced team of expertise and exceptional after sales service, our glass machines are highly praised by customers all over the world.